- sales@geveke.com.my

- +603-5569 5278/79

Our Products

Linkage to Manufacturer Portal: http://www.nikkiso.com/

Linkage to Manufacturer Portal: http://www.lewa.com/en/home/

Linkage to Manufacturer Portal: http://pulsation-dampers-hidracar.com/

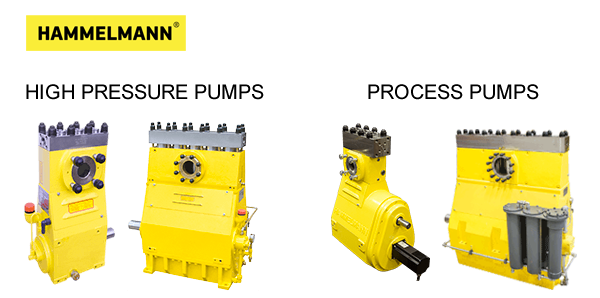

Linkage to Manufacturer Portal: http://www.hammelmann.de/en/index.php

DUTCH REGULATORS

Dutch Regulators is a company located in The Netherlands manufacturing stainless steel pressure regulators for gas and liquid applications. The main focus of Dutch Regulators is supplying high quality products, by understanding the needs of the end users.

Dutch Regulators is a company with many years of experience in designing and manufacturing high quality pressure regulators. Our certified Quality Management System according to ISO 9001:2015 is approved by Lloyds Register Quality Assurance.

Every regulator that leaves the company is fully tested according to the Pressure Equipment Directive PED 2014/68/EU. If necessary we invite a notified body to check the regulators. The materials of all parts are fully traceable by the marked batch-number. On request 3.1 material certificates can be supplied according to EN 10204.

Product range

The regulators are available as pressure regulators and back-pressure regulators in the size from 1/4” up to 2” connections.

The regulators are divided in the categories:

• Threaded regulators

• Flanged regulators

• Millibar regulators

Design pressures over the whole range of regulators are 16 bar, 50 bar, 280 bar and 420 bar.

There are models available with a large diaphragm for higher accuracy in the lower pressure ranges.

Production and sales

The engineering, assembly and testing of the regulators is done in house at Dutch Regulators. All parts are produced externally by carefully selected subcontractors, at the specifications of Dutch Regulators.

The welding of flanges is done externally.

For the sales and support we work with local distributors who can provide you with a good advice for the regulators and our additional possibilities

_____

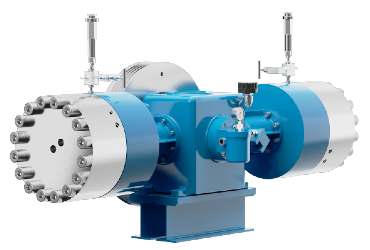

MEHRER COMPRESSORS

DIAPHRAGM COMPRESSORS

Single and two-stage diaphragm compressors for dicharge pressures up to 1000 bar (a) for absolutely leakage-free compression of toxic and flammable gases

AREAS OF APPLICATION

• Gas cylinder and trailer filling

• Hydrogen and natural gas refueling stations

• Helium compression e.g. for air bag test cycles

• Compression of corrosive and toxic gases, such as silane, chlorine or hydrogen sulfide

VARISCO PUMP

J SERIES

The J self-priming centrifugal pumps are used in applications requiring a fast-priming capacity from demanding suction heights combined with the ability to transfer and manage polluted, waste and abrasive fluids with suspended solids. The system features an inspect able pump casing, which also acts as a water tank allowing for early quick priming without auxiliary systems, simplifying system management and reducing maintenance times.

V SAXMAG SERIES

Increasingly widespread awareness about environmental issues has encouraged enterprises to design and install technical process plants that conform to the most recent health and accident prevention standards. Certain of the national and international standards, such as ATEX 94/9, make these requirements even more stringent. This is why VARISCO decided to develop magnetic drive pumps.

LB SERIES

Mechanically operated self-priming diaphragm pumps, for dense and viscous liquids that contain abrasives and suspended solids. They are used in the industrial and purification sectors (sludge, foams)

G SERIES

Varisco G external gear pumps are designed to ensure an extremely stable flow rate and minimal pressure pulsations. These pumps are commonly used for dosing and transferring low viscosity fluids with no suspended solids.

VULCAN SERIES

Progressing cavity screw pumps for liquids of any kind of viscosity that contain abrasives and a high percentage of solids or fibers. They are used in industrial plants.

ST-R SERIES

The ST-R self-priming centrifugal pumps are designed to facilitate unclogging operation field and ensure easy maintenance and high levels of reliability. The front inspection cover can be used to access all internal parts without disconnecting the the pipes and without removing the pump from the installation.

V SERIES

V volumetric internal gear pumps are used in applications where the management of clean fluids with high viscosities is required. They are used in all industrial applications where a delicate treatment of the pumped product is required, preventing chemical-physical alterations. Volumetric rotary, they ensure flow rates proportional to the rotational speed and con-stant pulse-free flows, regardless of the back pressure.

ARGO

Firefighting units in conformity with EN 12845 standards for sprinkler and hydrants. Arrangement with one or two electrically-driven or engine-driven pumps, complete with jockey pump. VISION: special firefighting applications.

_____

WANGEN PUMPEN

Technology of our pumps

Progressing cavity pumps

Modular, extremely robust, precise dosing, low pulsation. Large range of models and materials used for housings, rotor, stator, seals, joints ensures an optimum match to the medium being pumped. Our wide range of flanged connections and drives ensures the best possible solution for your installation and space

Twin screw pumps

Non-contact feed screw operation, efficient, compact. Developed to reliably convey low to highly viscous, volatile or gaseous products. Its design avoids dead space and stagnation zones. Due to their high speed range, they can be used as a process pump and as a cleaning pump.

WANGEN pumps are perfect for biogas industry, because of their combination of sophistication and longevity. They convey various types of biomass material, such as liquid manure from livestock farming, vegetable scraps and food waste as well as renewable raw materials, e.g. corn and gras silage, whole-crop-silage and dung, in each case mixed up with liquid manure or recirculates. We are the experts in conveying media in the sector of anaerobic digestion.

APPLICATIONS

• PUMPS FOR CONVEYING SUBSTRATE

• PUMPS FOR LOADING THE SEPARATORS

• PUMPS FOR FEEDING IN SOLID MATERIAL

Biogas /

Chemicals / Waste water and sewage systems

Agriculture / Food and drinks industry

_____

YTS AODD PUMP

MAKET &APPLICATION

Chemical

All chemical transfer applications including flammable & Toxic, Chemical dosing, Waste transfer.

Mining

Underground mining, Aboveground mining, De-watering, Solids & Some chemical transfer.

Automotive

Fuels (diesel fuel, gasoline, kerosene), Oils (gear, engine, waste), Windshield wiper fluid, Brake fluid, Radiator fluid & Anti-freeze applications.

Paint & Coating

Paints, Lacquers & Automobile industry (spraying) , Furniture production (coatings). High-resolution coatings (marine and shipbuilding).

Semiconductor

All Semiconductor & microelectronics solar panels industries.

High purity clean room applications for wafer cutting, Cleaning, Polishing & Etching.

Paper & Pulp

Manufacturing paper, Cardboard boxes, Book binding & Labels.

Food & Beverage

Loading, Unloading, Cleaning, Washing, Sanitizing, Transferring liquid hops, Bottling & Keg Filling at Distilleries / Breweries / Wineries.

Pharmaceuticals

Alcohol plants, Filter press, Batching, Bulk transfer, Personal hygiene, Chemical feed & Powder transfer.

Marine

Bilge, ballast & seawater transfer, Ship cleaning, Painting & Coatings.

Ceramic

Ceramic slip, Highly abrasive & dense applications.

Oil & Gas

On & offshore oil, gas applications, Fuel, Automotive & Machinery lubrication transfer.

Water Treatment

Chemical dosing, Waste transfer, Filter press, Sumps

_____

KRACHT

PUMPS

In addition to our standard products, we develop special pumps in close cooperation with our national and international customers. They provide specific solutions for the most diverse fluid technology applications.

Feel free to get in touch with us. We would be glad to advise you.

> Two-stage lubricating oil pump of a diesel engine

> Pre-lubrication pump of a dual fuel diesel engine

> Direct driven diesel oil pump

> Direct driven main lubricating oil pump with control valve

> Direct driven main lubricating oil pump for installation in the engine sump

> Internal gear pump for gear lubrication

> Gear pump for the lubrication of wind power gears

> Pumps with heavy-duty outboard bearing

PUMPS

Gear type flow meters for the most demanding tasks in fluid technology measurement technology. Our expertise guarantees functional solutions. Standardized and application-optimized.

> Fuel consumption measurement

> Characteristic curve generation of hydraulic components

> Gear oil filling

> Indirect, volumetric cylinder stroke measurement

> Ratio measurement in 2- and multi-component dosing systems

> Micro-flow measurement and micro-dosing

_____